FRP Rod Armoured Anti Rodent Fibre Optic Cable

CFO’s All-Dielectric Self-Supporting FRP armoured Fibre Optic Cable is designed for both aerial and direct buried applications.

The round FRP wire can provide the additional protection of the cable to prevent the “mega” rodent animal like a squirrel to damage the cable.

Features and Benefits

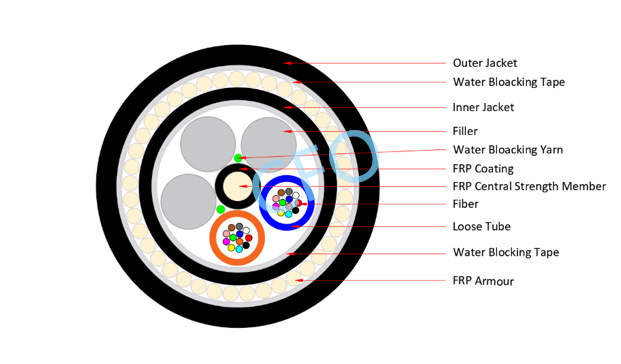

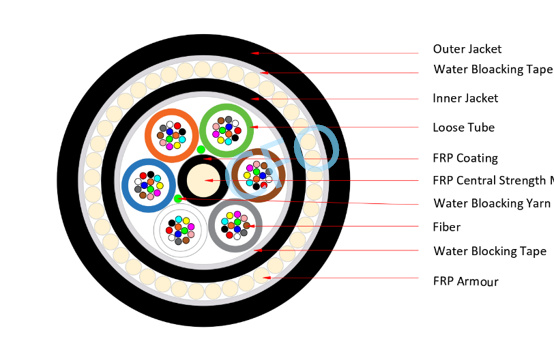

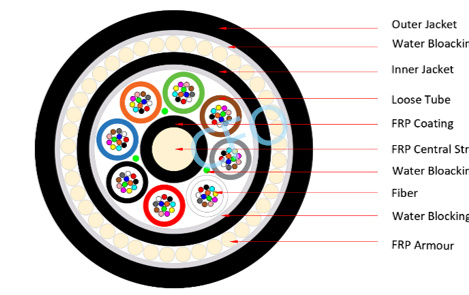

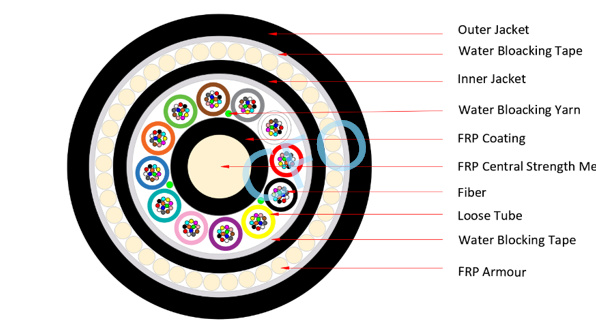

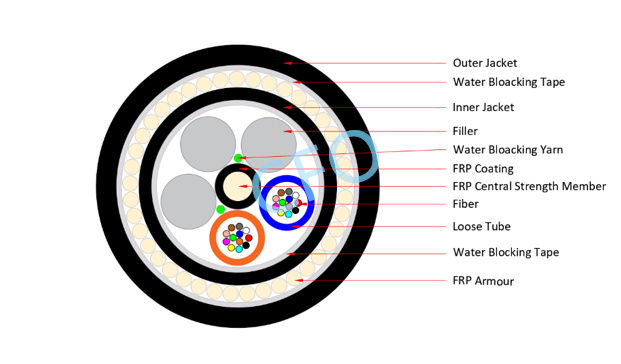

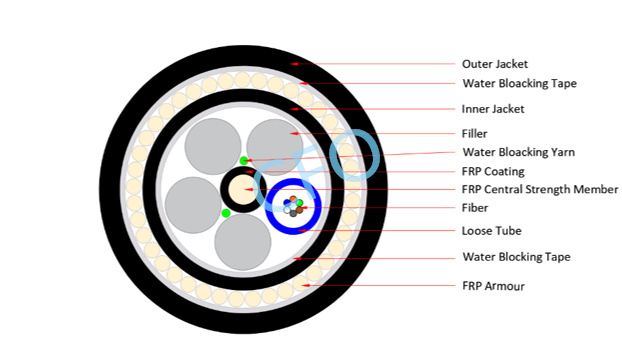

Optical fibers are housed in loose tubes that are made of high modulus plastic and filled with waterproof compounds.

FRP is wrapped around the inner sheath as a peripheral strength member.

Loose tubes are SZ stranded around the central strength member.

The cable core is covered with water blocking tape to prevent from water ingress.

Reference Standard

IEC 60794-1-1/2

IEC 60794-2

IEC 60794-3

IEC 60794-3-10/11

IEC 60794-1-2-E1/E3/E4/E6

IEC 60794-1-2-E11A

IEC 60794-1-2-F5B

IEC 60794-1-2-F1

Structure Design:

Main Features:

*Accurate process control ensuring good mechanical and temperature performances

*The material of loose tubes with good hydrolysis resistance and relatively high strength

*Tube filling compound providing key protection for fibres

*Combination of physical and chemical anti-rodent methods

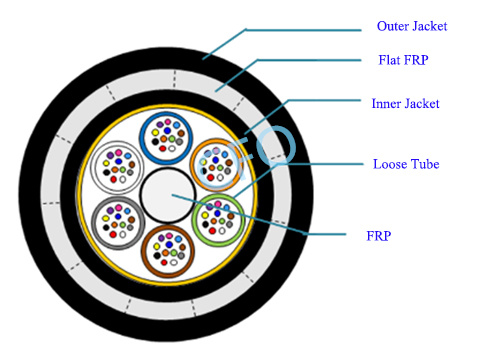

*Flat FRP armor providing the physical anti-rodent performance

*Anti-rodent sheath providing the chemical ani-rodent performance.which effecively delays the diffusion of anti-rodent additives to protect working environment and construction safe

*All-dielectric design,applicable to lightning-prone areas

*Applicable to aerial and duct installations with anti-rodent and anti-lightning reauirements

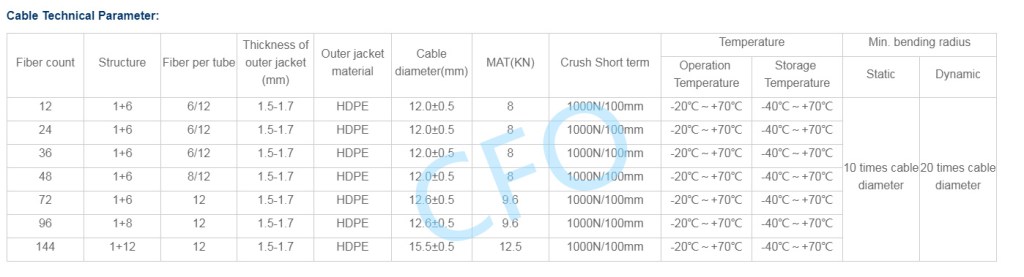

Cable Technical Parameter:

Specification of Optical Fiber:

Note.

1 .Flooding jelly compound default

2.The relevant technical parameters can be adjusted according to the customers’ demands;

3.The block water way can be adjusted according to the customers’ demands,

4.The design flame resistance,anti-rodent,termite resistant cable according to the customers’demands

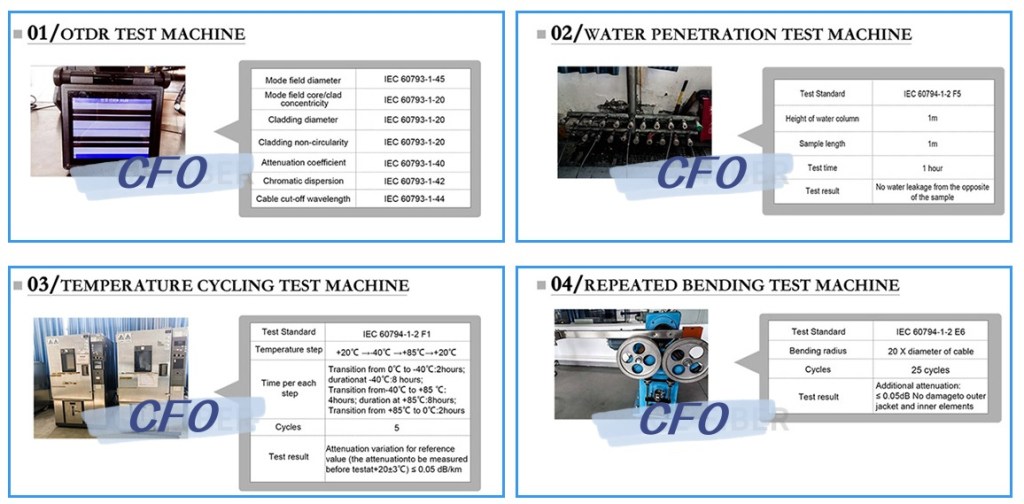

How to Ensure the Quality and Performance of Your Fiber Optic Cable?

We conrol the product quality from the raw maielal to the finish porduts. All the raw maielal shoud be tesied to match the Rosh standard when they arrived at our manuafacture. We contothe qualty duning the producing process by advanced techmolgy and equipments. We test the finished products according to he test standard. Approved by various proffesional opical and communication product institution. We also conduct various in-house testing in is own laboratary and test Center. we also conduct test with spcial arrangement with the chinese Government Ministry of QualityS upervision & Inspection Center of Optical Communication Products(QSICO).

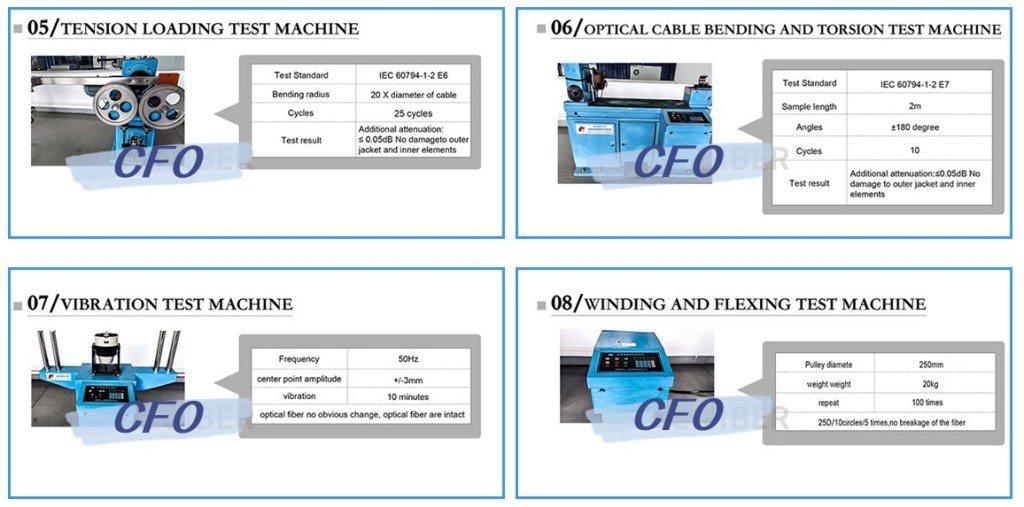

Quality Control . Test Equipment and Standard:

Feedback: In order to meet the world’s highest quality standards,

we continuously monitor feedback from our customers.

Forcomments and suggestions,please.contact us

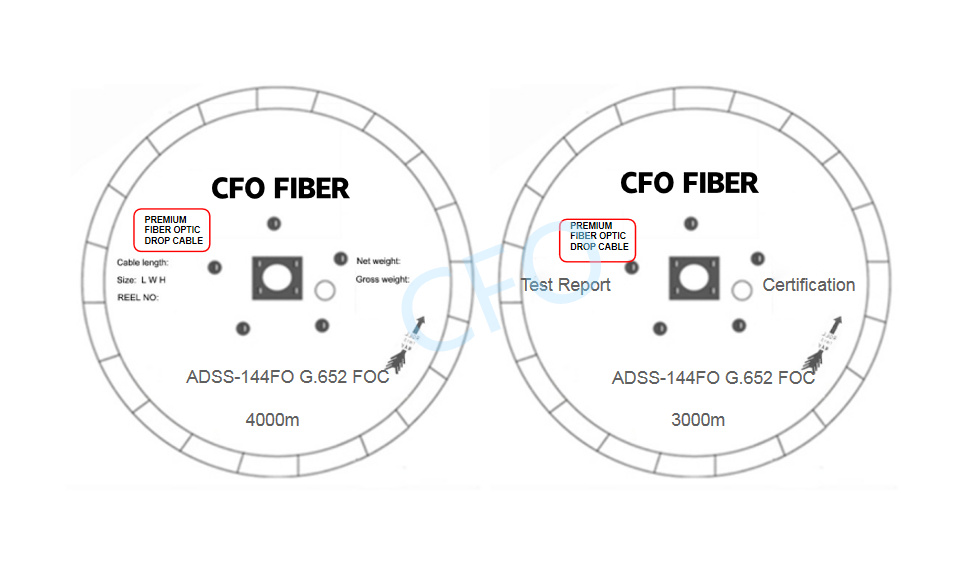

Packaging Details :

1-5KM per roll. Packed by steel drum . Other packing available according to client’s Request.

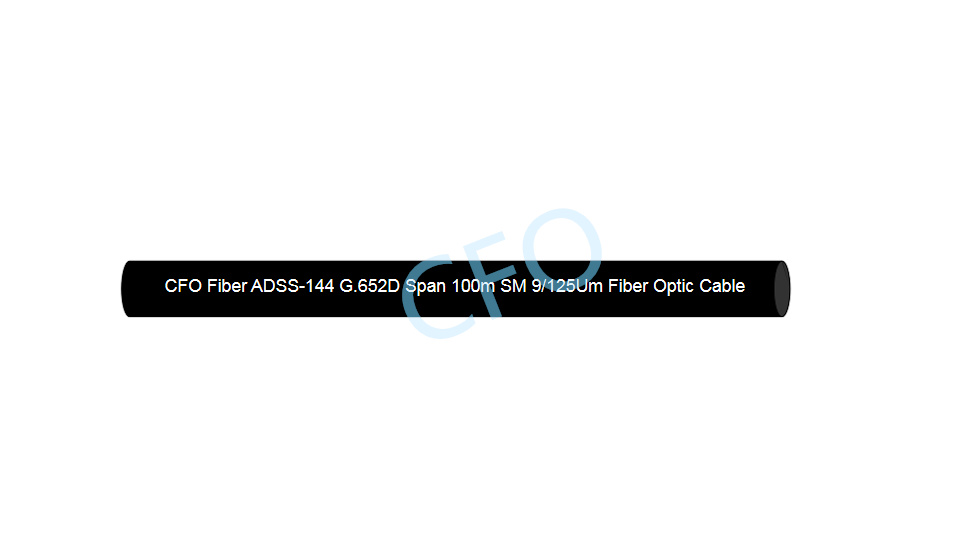

Sheath Mark:

The folowing printing(white hot folil indentations applied at 1 meter intenals.

a. Supplier. CFO or as customer required;

b. Standard Code(Product Type, Fiber Type,Fiber Count;

c. Year

of manufacture:7 years,

d. Length marking in meters.

Port :

Shanghai/Guanazhou/Shenzhen

Lead Time :

1)1-300KM: 15days

≥300KM: To be negotiated!

Note:

The Packing standard and details as above is estimated and final size & weight shall be confirmed before shipment

The cables are packed in carton,coiled on Bakelite & steel drum. During transportation, right tools should be used to avoid damaging the package and to handle with ease. Cables should be

protected from moisture, kept away from high temperature and fire sparks, protected from over bending and crushing. protected from mechanical stress and damage.

Anti Rodent Fiber Optic Cable

Rodents pose a significant threat to fiber optic cable, as their gnawing can cause serious damage to the delicate optical fiber. This article aims to discuss the commonly used methods for preventing rodent bites

The methods of anti-rodent

1. Chemical methods. It is the addition of a spiciness to the sheath of the optical cable. When rodents bite on the sheath, the spiciness can strongly stimulate the oral mucosa and taste nerves of rodents, causing them to give up biting. The chemical properties of spiciness are relatively stable, but when the optical cable is used in long-term outdoor environments, the spiciness will gradually leak out of the sheath due to factors such as water solubility, making it difficult to ensure the long-term rodent prevention effect of the optical cable.

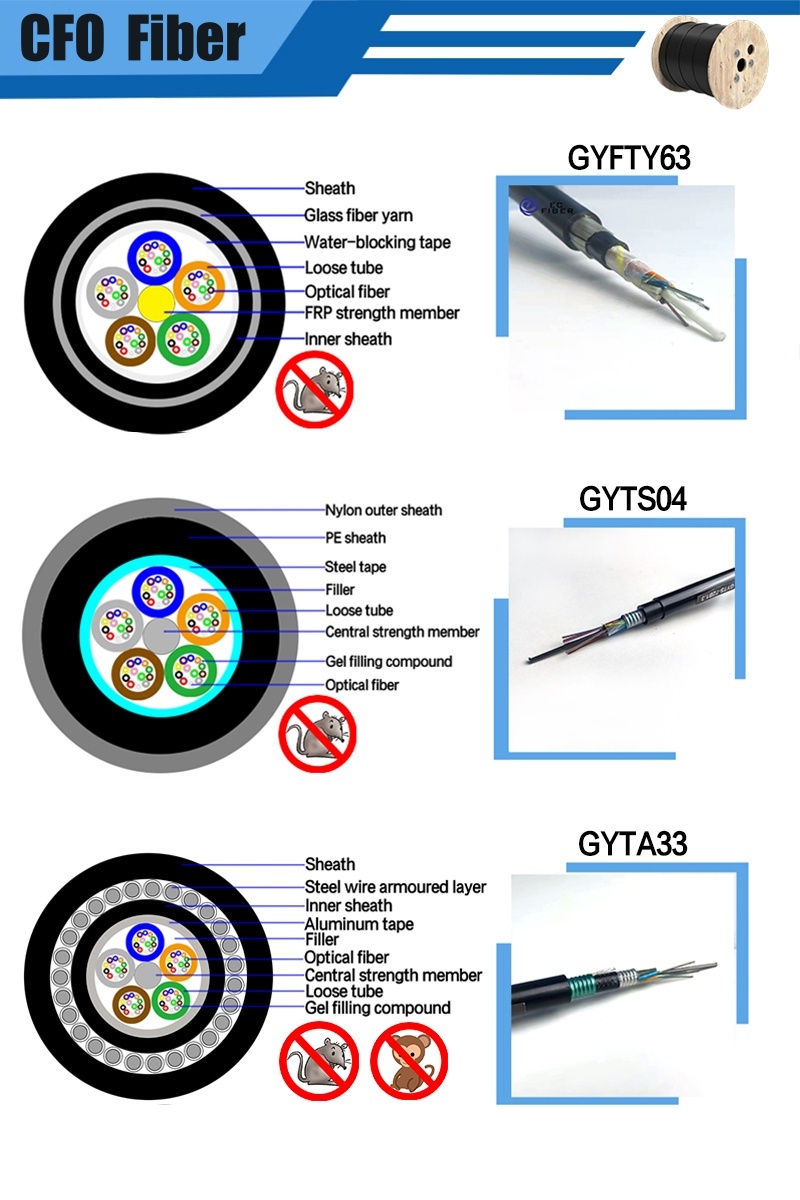

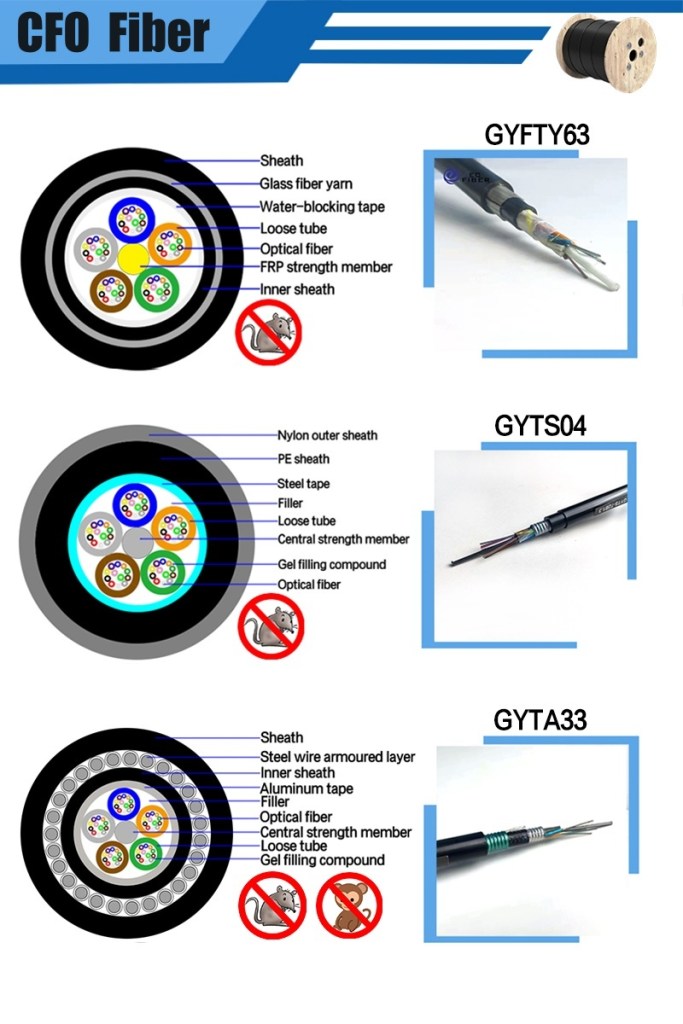

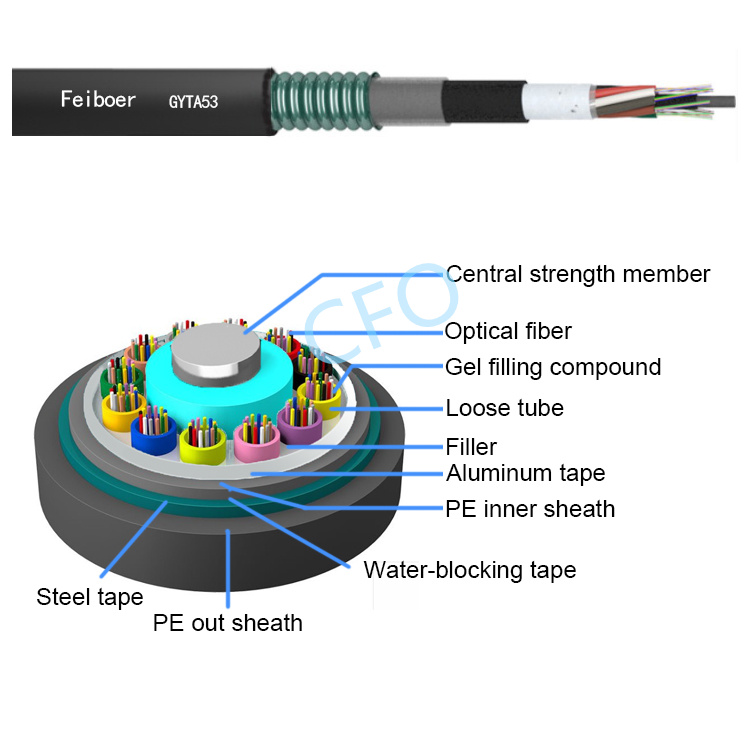

2. Steel armor. It is to apply a hard metal reinforcement layer or armor layer (hereinafter referred to as the armor layer) outside the core of the optical cable, making it difficult for rats to bite through the armor layer, thus achieving the purpose of protecting the cable core. Metal armor is a conventional manufacturing process for optical cables, and the manufacturing cost of optical cables using armor protection method is not much different from that of ordinary optical cables. Therefore, currently, anti-rodent optical cables mainly use armor protection method.

3.Glass Yarn. It is to add a layer of glass yarn or FRP (Fiber Reinforced Plastics) between the inner and outer protective layers of the optical cable, as shown in Figure 2. Due to the extremely fine and brittle nature of glass fibers, the shattered glass debris during rodent biting can damage the rodent’s oral cavity, causing fear of optical cables.

How to choose an anti-rodent fiber optic cable

The Mohs hardness of rodent incisors can reach 3.0-5.5, with the highest being close to stainless steel. According to the research results of Belden, a Dutch company, steel wires and strips have the highest effectiveness in rodent prevention, at around 95%. The schematic diagram of the effectiveness of optical cable armor in rodent prevention is as follows.

From the figure, it can be seen that the chemical method is not efficient,furthermore it is not environmentally friendly. Therefore, the main method currently used is steel wire and steel tape. In some overhead applications with weight limit and less severe rodent infestation, glass yarn can also be considered.

When use armored fiber optic cable, The key to preventing rodents is “penetration resistance”, which means the ability of armor to prevent penetration. The general penetration resistance is closely related to the thickness of the steel tape. According to research, steel tape with a thickness of 0.2, 0.18, 0.15, and 0.13 millimeters can respectively achieve penetration resistance of 120N, 95N, 76N, and 59N. When the thickness of the steel tape is the same, the corrugated steel has a much higher penetration resistance than the flat type steel, while the stainless steel is much better than the chrome plated material steel, and its corrosion resistance is several times higher than that of ordinary steel. According to relevant research, the biting force of mice can reach 26-50N, and the biting force of squirrels and bamboo rats can reach 80-120N. Therefore, it is generally required that the thickness of the steel tape should not be less than 0.2mm.

Thickness of steel tape Resistance

0.2mm 120N

0.18mm 95N

0.15mm 76N

0.13mm 59N

Here are some suggestions:

1. Direct Bury applications

Usually, GYTA53 is a good choice. while sandy soil areas where Frequent rodent activity happened,GYTS53 will work better.

2. Duct Applications

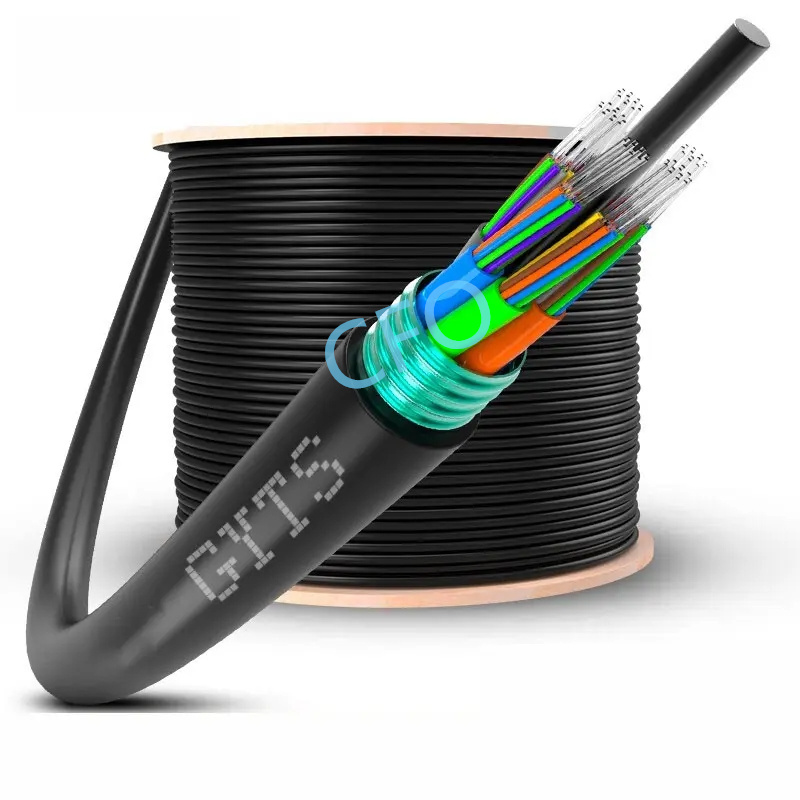

Generally, GYTS has good rodent prevention ability;

But for the applications in the wild where rodents are very active,

GYTS53 is more suitable.

3. Aerial Applications

Usually, glass yarn or FRP armor is a good choice for aerial applications. It is mostly non-metallic, light weight.

But still some people choose GYTS for its better anti-rodent ability. Even choose GYTS53 used in the wild where frequent rodent activity happened. It is heavy but it has excellent anti-rodent ability.

Some other ways of anti-rodent

Make the diameter bigger than 45mm

Install plastic tube with larger diameters in the directly buried application. The experiment shows that the larger the cable diameter, the corresponding anti-rodent ability will increase. When the outer diameter of a tube is greater than 45mm, it can basically avoid mouse bites. Therefore, using silicon core tubes larger than 45mm in the directly buried application can effectively reduce rodenticide. At the same time, stainless steel wire sealing is needed to prevent small rodents from entering the pipe.

Make the depth no less than 1.2 meter

Ensure direct burial depth no less than 1.2m. 80% to 90% of rodents living in underground caves dig at depths less than 0.5 meters; The depth of movement of hamsters is about 1m; The drilling depth of bamboo mice is about 2 meters. Ensuring that the depth of the cable trench is greater than 1.2 meters can avoid most rodent damage.

If you have any questions about the above, please leave a comment below.

Thank you!

Or feel free to contact our professional consultants.

Skype: leorumin1987

Email: fibercableoem@foxmail.com

Linktr.ee: https://linktr.ee/LEOFIBER